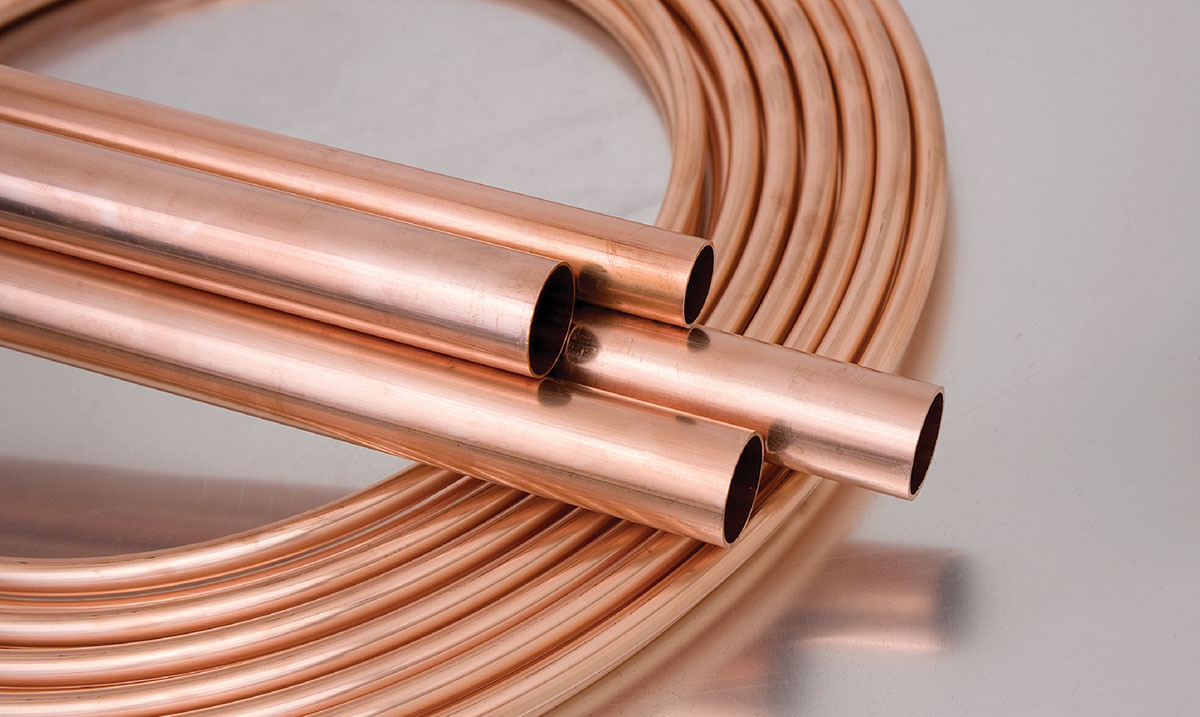

The Relevance of Top Quality in the Manufacturing of Copper Products

The significance of top quality in the production of copper products prolongs far past plain conformity; it is integral to optimizing efficiency across various industries. As we check out the multifaceted nature of top quality, the question arises: just how can producers balance these challenges to accomplish quality?

Impact on Product Performance

The top quality of copper products plays a crucial function in identifying their overall performance in numerous applications. Top quality copper displays premium electrical conductivity, thermal conductivity, and corrosion resistance, which are necessary qualities for markets such as electronics, building and construction, and automobile. In electrical applications, for instance, high-purity copper decreases power loss throughout transmission, making certain effective power delivery. This effectiveness is important for the durability and reliability of electric systems.

Furthermore, the mechanical residential or commercial properties of copper, consisting of ductility and tensile stamina, significantly affect its efficiency in producing procedures. Copper items that fulfill rigorous quality requirements can hold up against substantial anxiety without deforming, thus boosting toughness and reducing the chance of failing popular environments.

Additionally, the surface coating of copper items influences their efficiency. A smooth, well-treated surface area can protect against oxidation and other types of destruction, ultimately prolonging the life of the element. In summary, the quality of copper products directly affects their capability, reliability, and longevity throughout numerous markets, making it crucial for producers to stick to extensive quality assurance measures throughout the manufacturing process.

Cost Ramifications mediocre

Purchasing premium copper products is important, as the cost implications mediocre can be significant for suppliers and end-users alike. Low quality copper can bring about raised failing rates, resulting in pricey repairs and replacements. Suppliers may face significant downtime as malfunctioning products demand remembers or remodel, interrupting manufacturing schedules and affecting general efficiency.

From an end-user viewpoint, the implications are similarly serious. Poor-quality copper can result in inefficiencies and increased functional costs, as devices may require even more frequent maintenance. Inevitably, the initial cost savings obtained from choosing lower-quality copper products can be eclipsed by these long-lasting expenses, making the quest of quality not simply a matter of performance, yet an important financial factor to consider in the manufacturing field.

Safety And Security and Conformity Requirements

Guaranteeing safety and security and conformity requirements in the production of copper products is important to keeping operational honesty and safeguarding both workers and consumers. The production process have to stick to rigorous laws stated by organizations such as the Occupational Security and Wellness Administration (OSHA) and the Environmental Security Agency (EPA) These policies describe vital safety and security techniques, consisting of appropriate handling of resources and waste administration, making certain a risk-free work environment.

Furthermore, conformity with market standards such as ASTM International and ISO qualification is important. These organizations provide standards that help suppliers implement finest techniques in quality control and precaution. Normal audits and find more examinations ought to be conducted to ensure adherence to these criteria, as non-compliance can cause dangerous conditions and potential legal implications.

Client Depend On and Complete Satisfaction

Count on and complete satisfaction among clients play a pivotal function in the success of copper product makers (Copper Products). Premium copper items not just fulfill strict sector requirements yet also fulfill client assumptions, cultivating commitment and repeat service. When consumers are certain in the high quality of the items they acquire, they are more probable to develop a long-term connection with the maker, which can bring about referrals and favorable word-of-mouth

To develop this trust fund, manufacturers must focus on quality assurance throughout the production process, ensuring that each copper thing satisfies or surpasses requirements. Transparency in producing practices, coupled with commitment to customer support, strengthens the understanding of dependability. In addition, prompt distribution and responsiveness to consumer queries dramatically enhance satisfaction degrees.

Consumer comments must be proactively looked for and incorporated into product development cycles to constantly improve offerings. Involving clients in dialogue concerning their choices and needs grows a sense of collaboration, additional solidifying their count on the maker. Ultimately, an online reputation for top quality and customer-centric methods differentiates effective copper product manufacturers in an open market, laying the foundation for sustaining client connections.

Lasting Business Success

A supplier's commitment to high quality is indispensable to attaining lasting organization success in the affordable copper items market. High-quality products foster client loyalty, making sure repeat business and favorable recommendations that drive growth. In a market where dependability and performance are vital, business that prioritize top quality over cost-cutting actions are much like this more likely to stand apart.

Furthermore, regular high quality minimizes the occurrence of problems and rework, resulting in lower functional prices and increased effectiveness. This streamlined production procedure enables makers to assign resources properly, allowing for financial investments in technology and modern technology. Services that adjust to market adjustments and invest in high quality enhancements are much better placed to fulfill evolving customer demands.

In addition, keeping stringent high quality requirements enhances a business's online reputation, bring in new clients and potential partnerships. A durable track record for top quality can serve as a differentiator in crowded markets, opening doors to financially rewarding agreements and collaborations.

Ultimately, an unfaltering commitment to quality not only makes certain compliance with market policies however also grows a lasting business version. By embedding quality right into every aspect of the production procedure, companies can protect their place as leaders in the copper products industry, leading the way for sustaining success.

Verdict

In verdict, the importance of quality in copper product production is critical. As markets progressively rely on copper for important applications, keeping extensive quality control is important to secure a competitive benefit and maintain a trustworthy market existence.

The relevance of high quality in the production of copper items extends much past simple compliance; it is important to optimizing efficiency across various markets. In summary, the high quality of copper products straight influences their performance, dependability, and long life throughout various fields, making it crucial for producers to adhere to rigorous high quality control steps throughout the production process.

A manufacturer's commitment to quality is indispensable to achieving lasting organization success in the competitive copper products market.

Comments on “Why Copper Products Are Necessary for Electric Applications and Effective Circuitry”